TS EN 12810-1, 12810-2, 12811-1, and 12811-2 Certified Durable and Safe Scaffolding Solutions

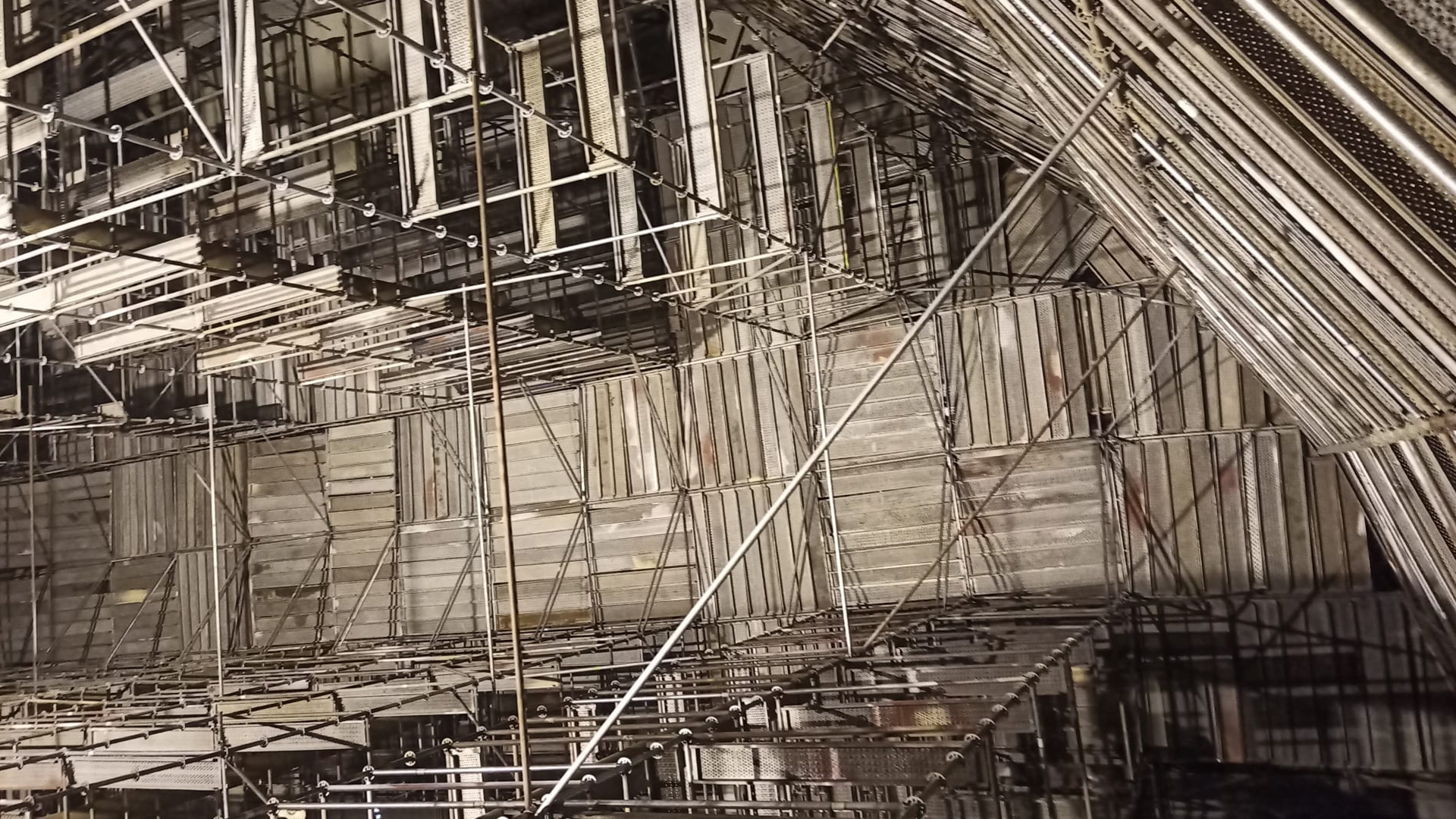

The Flanged Scaffolding System offered by Turkey Scaffolding is comprised of products manufactured to meet the highest quality standards, fully certified with TS EN 12810-1, 12810-2, 12811-1, and 12811-2 standards.

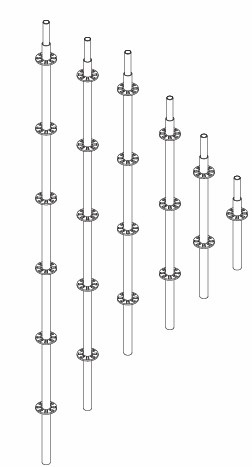

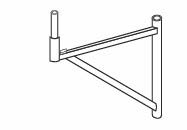

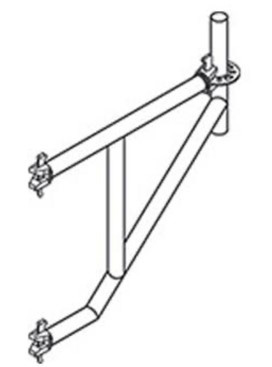

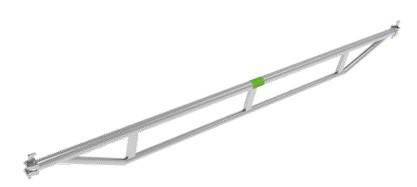

Our vertical pipes are made from 48*3.0 mm industrial-grade pipes, while the horizontal and diagonal connections are produced using 48*2.5 mm TSE-certified pipes that have undergone rigorous mechanical testing. All connection elements and platforms are manufactured with precision through robotic cutting, drilling, and welding processes and are hot-dip galvanized in accordance with TS 914 EN ISO 1461 standards to ensure maximum durability and protection.

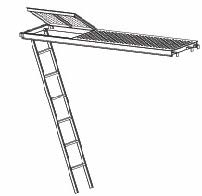

Flanged Scaffolding Assembly Steps

The assembly of the Flanged Scaffolding System follows these steps:

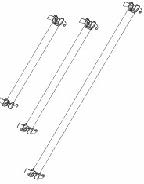

- Setting Base Jacks: According to the scaffolding assembly plan, the correct heights and positions of the base jacks are determined.

- Mounting Initial Frames: Initial frames are mounted onto the base jacks, distances are set using horizontal connections, and the system is leveled properly.

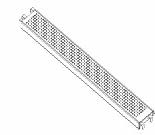

- Installing Platforms: Laddered platforms are installed onto horizontal connections in designated areas. The first module, which includes diagonal braces, is created by assembling vertical pipes with horizontal and diagonal connections.

- Completing the First Level: The first level assembly is completed.

- Mounting Upper Platforms: Upper-level platforms are mounted, paying close attention to ladder details.

- Building the Second Level: Using diagonal braces again, vertical pipes, horizontal connections, and diagonal braces are installed to complete the second level.

- Finalizing the Second Level: Toe boards are mounted, and the second level is finalized.

- Securing to the Façade: The scaffolding system is anchored to the façade according to the project design.

- Continuing Installation: The installation process continues in the same order as outlined in the project plan.

Project Management

For every project using the Flanged Scaffolding System, architectural drawings are meticulously reviewed by our engineering team. Detailed material quantity calculations are performed to ensure accurate material requirements, enabling optimal material utilization for your project.

Assembly and Disassembly Service

In addition to providing high-quality scaffolding systems, Turkey Scaffolding also offers professional assembly and disassembly services performed by our expert team. Based on the specific requirements of your project, scaffolding installation and removal are carried out efficiently and professionally, ensuring every phase of your project is completed seamlessly.

With its commitment to safety, quality, and precision, Turkey Scaffolding continues to provide durable and innovative solutions for construction projects worldwide.

info@turkeyscaffolding.com

+90 551 601 31 61